Welcome to Shandong Houde Industrial Equipment Co., Ltd!

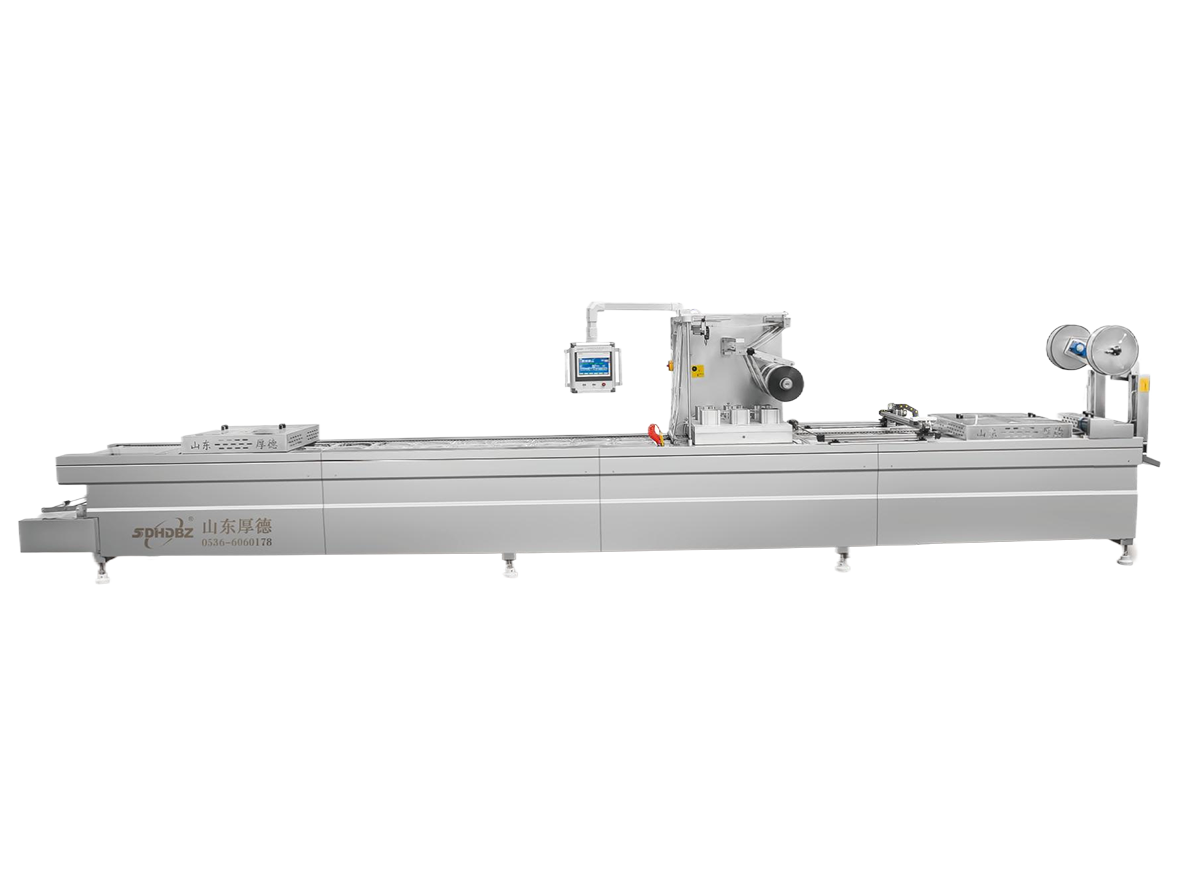

Computer automatic vacuum packaging machine for medical consumables

Computer Fully Automatic Medical Consumables Vacuum Packaging Machine

Strong performance, wide applicability, various forms, high efficiency

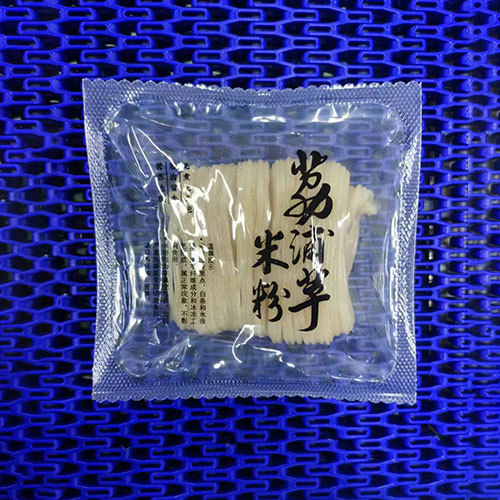

● The computer automatic vacuum packaging machine for medical consumables adopts a continuous stepping method, which is formed by the lower roll film and sealed by the upper roll film.

• Filling can be done manually or mechanically, as required.

● It can be vacuumed or filled with protective gas, and then sealed by hot pressing.

Classify:

Products

Keywords:

Automatic Medical Consumables Vacuum Packaging Machine

Computer automatic vacuum packaging machine for medical consumables

The machine has strong performance, wide applicability, various packaging forms and high working efficiency. Widely used in various food and non-food packaging fields

Strong performance, wide applicability, various forms, high efficiency

● The computer automatic vacuum packaging machine for medical consumables adopts a continuous stepping method, which is formed by the lower roll film and sealed by the upper roll film.

• Filling can be done manually or mechanically, as required.

● It can be vacuumed or filled with protective gas, and then sealed by hot pressing.

Classification:

Products

Key words:

Automatic Medical Consumables Vacuum Packaging Machine

Email:

Product Details

Equipment performanceEquipment performance

The computer automatic vacuum packaging machine for medical consumables adopts a continuous step-by-step method, which is formed by the lower roll film and sealed by the upper roll film.

The packaging process is automatically completed by the machine, according to the need, filling can be achieved by manual or mechanical. The rolled film is pulled to step by step, passes through the preheating zone and the heating zone, is formed by air pressure, vacuum or die, and enters the heat sealing zone after filling the material in the filling zone. In the heat seal area, the upper roll of film is covered on the forming box after passing through the guide roller. Depending on the packaging needs, can be vacuumed or filled with a protective gas treatment, and then hot-press sealing. After the heat sealing is completed, the production batch and production date can be printed. Then by cross-cutting, slitting, forming packaging finished product. The cut edge material can be collected and cleaned by the waste recovery device.

Equipment OverviewEquipment Overview

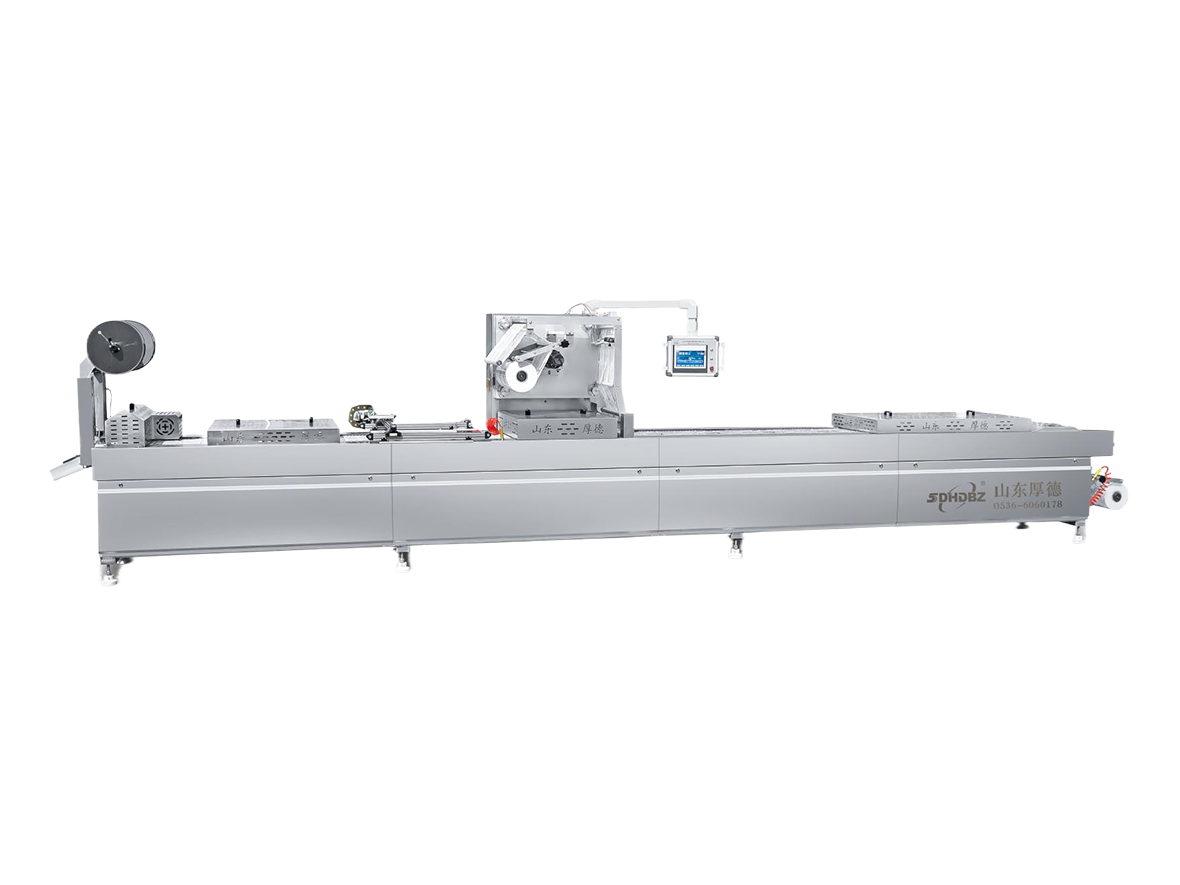

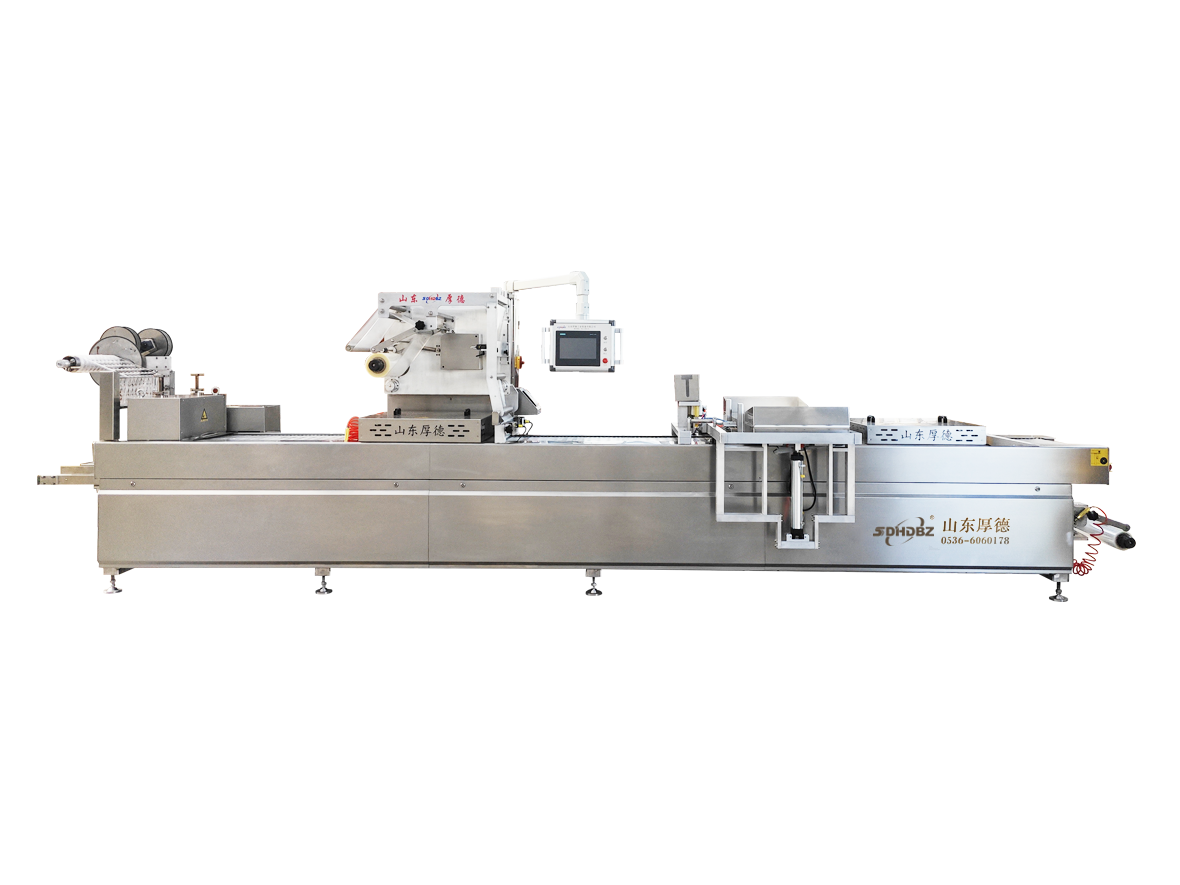

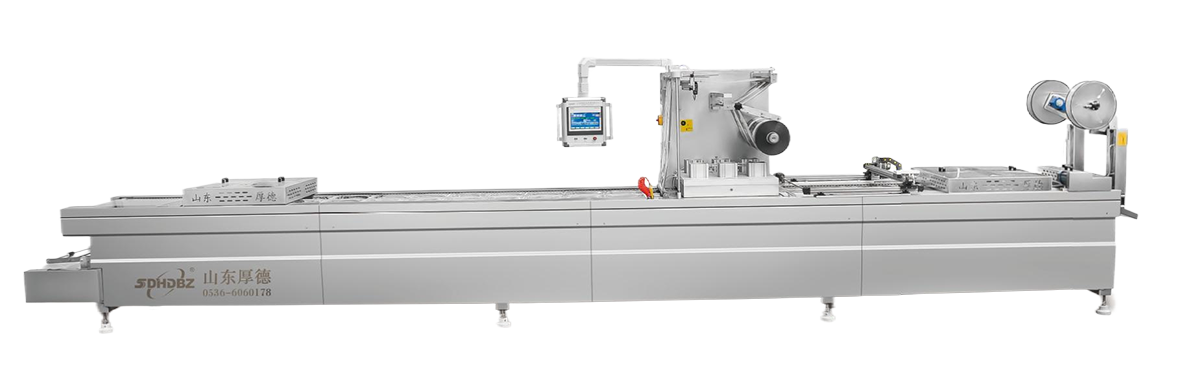

The computer automatic vacuum packaging machine for medical consumables integrates the functions of film stretch forming, material filling, vacuuming, inflation, heat sealing, coding/spraying, slitting, etc. It has the function of a packaging production line on one mechanical equipment. The machine has strong performance, wide applicability, various packaging forms and high working efficiency. It is widely used in various food and non-food packaging fields.

Technical parameters

Slide the table left and right to view all parameters

| Model | Upper membrane width | Lower film width | vacuum degree | Compressed air | Power | Power | Whole machine weight | Overall dimension |

| DLZ-420 | 396mm | 422mm | ≤ 200Pa | ≥ 0.6MPa | 380V 50HZ | 16KW | 1700kg | 6800 × 1100 × 1900mm |

| DLZ-520 | 496mm | 522mm | ≤ 200Pa | ≥ 0.6MPa | 380V 50HZ | 18KW | 2100kg | 7800 × 1200 × 1900mm |

Can be customized according to customer requirements processing

Product advantages

Factory direct supply

Factory direct sales

Convenient operation

Convenient operation

Seiko production

Seiko

Stable performance

Stable performance

Rugged and durable

Strong and durable

After-sales worry-free

No worries after sale

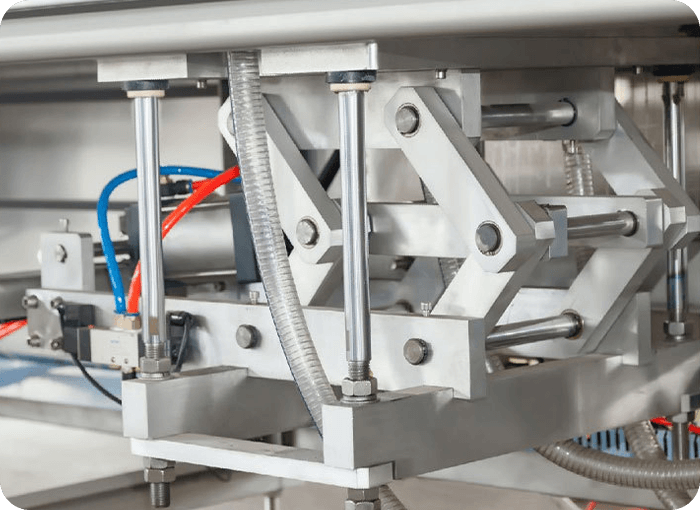

Stainless steel frame construction

Stainless SteelFrame structure

- High structural strength, corrosion resistance

- Each fixed position screw hole is processed by high precision laser once

- Ensure the accuracy of the assembly of the components, so that the whole machine runs smoothly.

Lifting device

LiftingDevice

- Separate positioning does not take the main frame as the main connecting body

- Not because the installation ground is uneven

- Sealing, vacuum and molding failures caused by lifting deformation

Mechanical Performance Power Brake

Mechanical Performance Power Brake

- Ensure the stability and even force of the film during the packaging process to avoid wrinkles, curling, and other issues with the packaging film.

- The entire power brake system has stronger stability and can extend the service life of the brake system; Replacing packaging film is simple and easy to operate; Efficient linkage with cursor collector; At the same time, it avoids the problem of cyclic adjustment of numbers due to changes in packaging film diameter during equipment operation.

Waste film collection device

waste filmCollecting device

- Waste film collection device adopts intelligent detection device

- The device has no noise, simple and beautiful appearance

- The total power consumption is only 0.18KW/hour and the running state can be automatically adjusted according to the length of the waste film.

Customer Site

The company is market-oriented, attaches importance to the adjustment of product structure, constantly updates and develops new products, and the level of products and technology has reached international standards, which is the ideal choice for users. The prospect is brilliant, and there is a long way to go. We Houde people will, as always, pursue the tenet of "harmonious development, integrity and win-win", and use Seiko's excellent products

Cooperative

We will, as always, pursue the tenet of "harmonious development, integrity and win-win", and work hand in hand with people of insight around the world to improve and take care of human health with Seiko's excellent products.

Online Consulting

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.

Products